A Screw Loose

Fun story to bait you into this installment of the Captain's Log. I do actually end up talking about some engineering, and work stuff, but figured some comedic relief was needed after the last few "heavier" posts.

Cooked

I was on the first train south this morning, for one of my long haul days. I managed a couple hours of sleep on the way - a substantial victory. With 27 minutes left in what I thought was a really weird dream, the conductor clicked over the PA:

Folks, we'll need to evacuate the train. Please find your way to the platform, we have a fire in one of the coaches, this train isn't going anywhere for quite a while. You'll have to hitchhike on the Commuter Rail the remainder of the distance to Boston.

After taking my time realizing it wasn't a dream, and that it was in fact some kind of fire, I exited the train. Just like any rational adult, I started walking towards the smoke to see if anything interesting was gonna happen ¯\_(ツ)_/¯

Suspended underneath the coach of interest is a large black box, that if Amtrak is to be believed, contains "BATTERIES". By the time the train stopped, they had cut power to/from the car, and the worst had subsided, but there was definitely still smoke coming from between the platform and the train. Usually, I'm pretty skeptical of anything the government says, but I'll take their word that those were in fact batteries, as the whole platform was treated to the finest aroma of questionable chemicals, ozone and a hint of charred wiring!

It was giving cooked?

I did eventually get to work, and when I did, Amtrak was kind enough to notify me that my train had been delayed an hour and a half earlier, go figure.

Funny enough, the train I'm on now, is the same one that caught fire this morning! There's a lesson in resiliency and perseverance somewhere.

New Commute Quirks

As I settle into something of a routine, I've made a series of observations about my new commute, and some of its characters.

Total Commute Time: 15 hours/week

At 1:30 each way on average, this actually isn't the worst commute I've had. I used to commute from Brookline, MA to East Greenwich, RI every day which was 1:30 in the car, or 1:45 on the train. In reality, my commute is more lopsided with Tech Center days being about 7 hours of travel, while the stroll into my workshop in Maine is about 15 minutes. It is what it is.

Back of the Bus

The Downeaster is the school bus for corporate commuters of Maine, New Hampshire and Massachusetts, and the Cafe Car is very much the back of the bus. It gets ROWDY on a Tuesday. It's like a louder, grittier version of Cheers on wheels. Everyone is throwing back beers, there's drama, and everyone knows your name.

Wait, did you say 7 hours? In one day? WTF!?!

It's not that bad... Sometimes.

I drastically overestimate what can reasonably be accomplished in a workday. Then I rush all day, work up to the last possible minute, sprint to North Station and ride the train home in sadness and disappointment. When you need to get more done, or need to be somewhere else right now, the train is a tin can. You're trapped.

Days I cross the last thing off my todo list around 4:00 are heavenly! I can stroll leisurely back to North Station. Then I ride the whole way home in peace. I should get back in the habit it reading, but for now I've been using the time to get back in touch with music - digital crate digging so to speak.

More often than not though, the train just ends up being an extension of my workday. The Internet is consistently slow enough to keep me off of YouTube, but fast enough to be uninhibited in any other task. It's the perfect chunk of time to catchup on emails, read industry news, or write a blog!

This concludes 357 words on the most boring part of everyone's day.

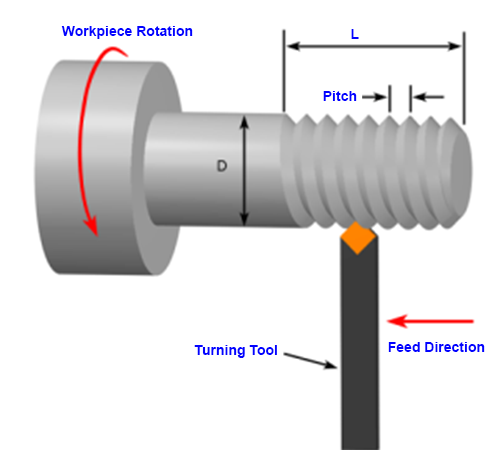

CNC Turning

CNC - computer numeric control

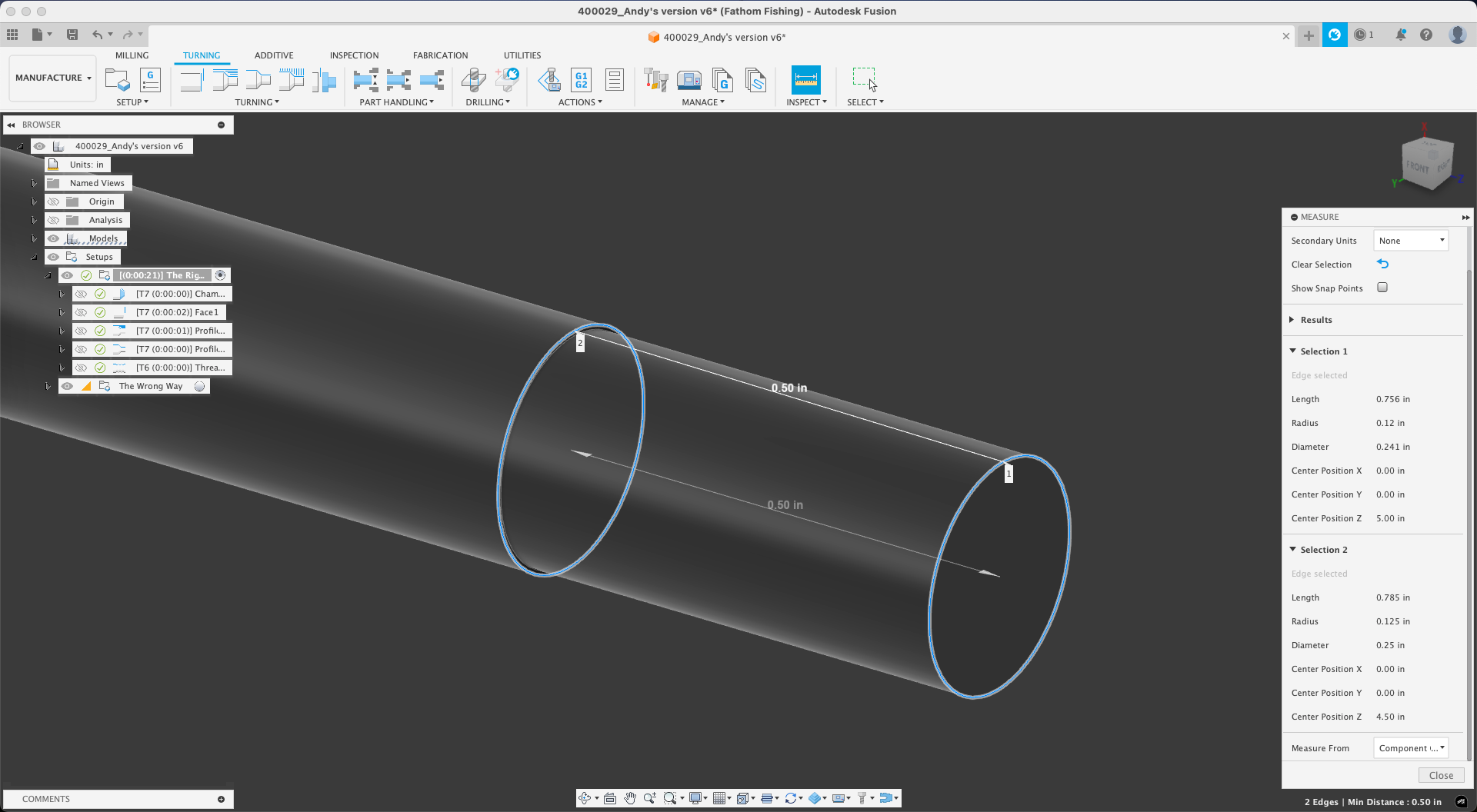

Like any other computer, CNC machines are programmed with code. This is really cool, because you can take a 3D model, use the model to generate a set of instructions, and run those instructions on the machine. It's quite simple when you don't think about it much more than that...

The Tech Center has a CNC lathe that's absolutely incredible, but equal parts amazing and terrifying. CNC lathes have a lot more simultaneous moving parts and idiosyncracies without some of the guardrails that mills I've used have. As of three weeks ago, it scared me so much, I wouldn't even look at it. If I couldn't see it, it didn't exist and it couldn't hurt me.

I finally came to a point where I needed to use it, and so I chose a handful of what I thought were pretty straightforward parts to learn with. Boy I couldn't have been more wrong.

Andy's 3 Parts of Dread and Despair

- Bearing Adapter

- Aluminum 6061

- This part is hard because it has a bore for a bearing that needs to be between .7500" and .7504", so I have .0004" to spare.

- For context: a human hair is about .003"

- Standoff A

- Stainless Steel 316

- Difficult to machine because it's small and Stainless Steel is physically very hard, and likes to harden even more at random

- Standoff B

- Nylon

- This part is hard because it's basically a wet noodle. It's long, skinny and Nylon is super soft and flexible. When you try to cut it, it doesn't cut, it wants to deform and warp instead.

For anyone who wants to nerd out about threads

Standoff B, has an external thread on one end, like a screw. While tirelessly trying to machine it, I've learned a lot about threads in the last 24 hours.

Threading For Beginners

In a lot of cases, you can just cut these threads by running a die over one end - it's really straightforward, but very annoying if you need incredibly precise threads, or need threads on more than a handful of parts.

When you need to automate the process, or have more control over the threads themselves, you can cut them with a lathe!

Seems simple, right? Wrong. Or maybe I'm just wrong and have made this all more difficult than it needs to be, but alas...

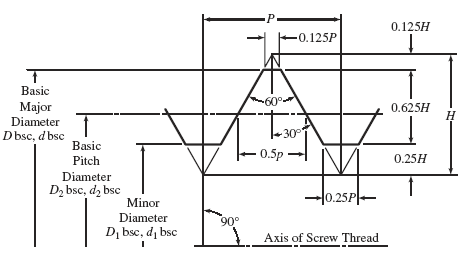

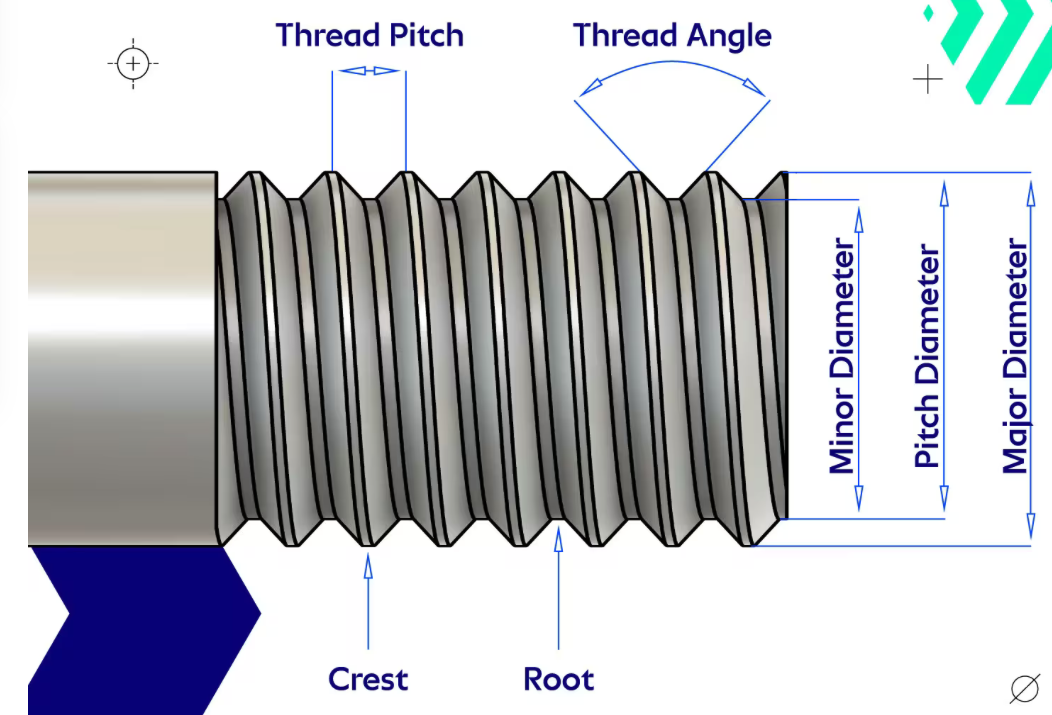

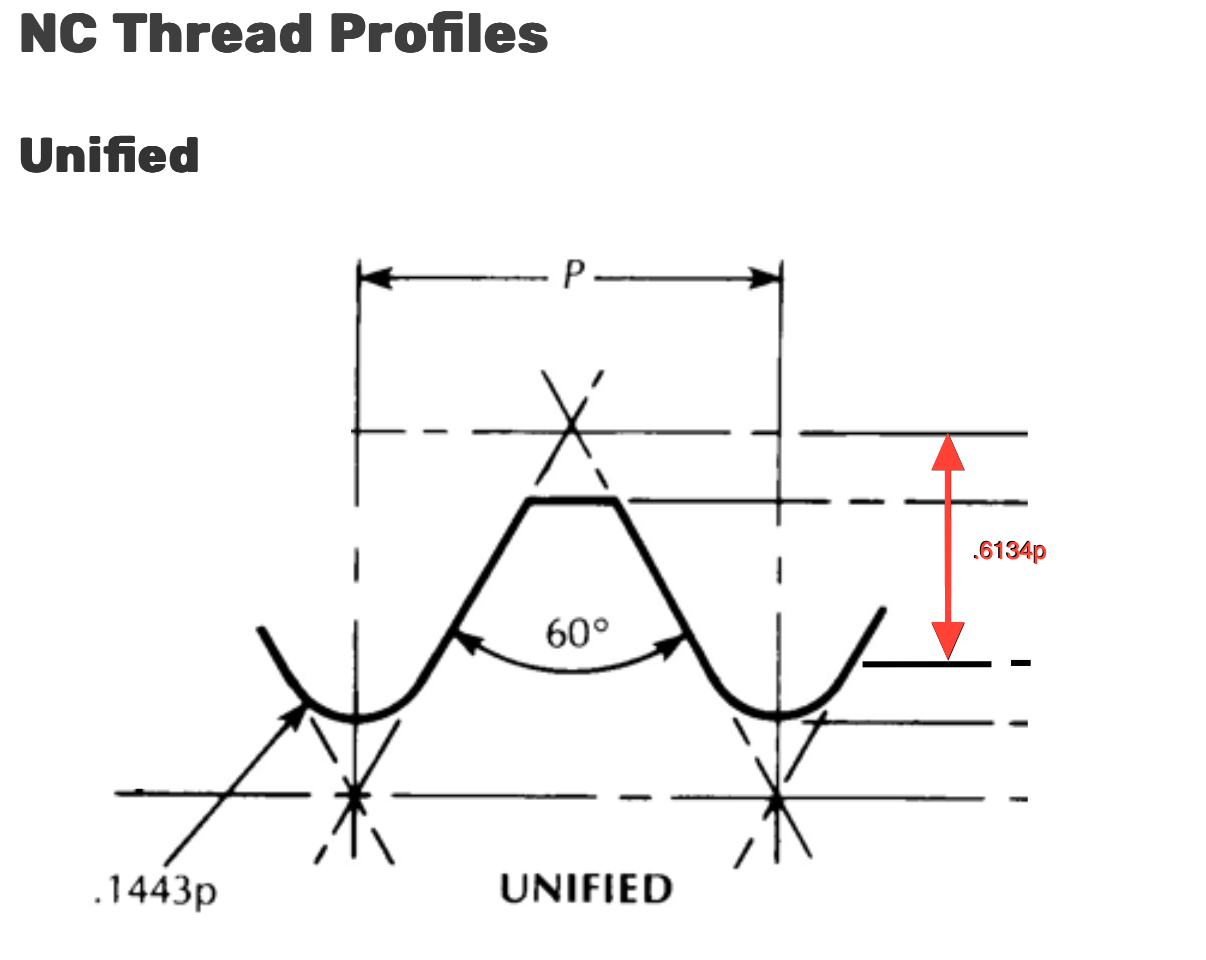

Thread Geometry

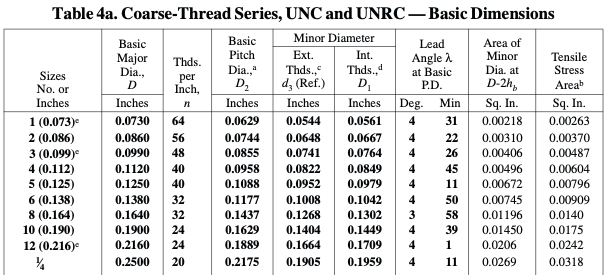

Threads have a number of properties that drive their size, and geometry. Here's a simple(ish) first look. We see Basic Major Diameter, Minor Diameter and Pitch (P). For example, one of the most common screws around is a 1/4-20. It nominally measures 1/4" at the largest diameter, and has 20 threads per inch of screw length.

Left from Engineers Edge, right from Accu Components

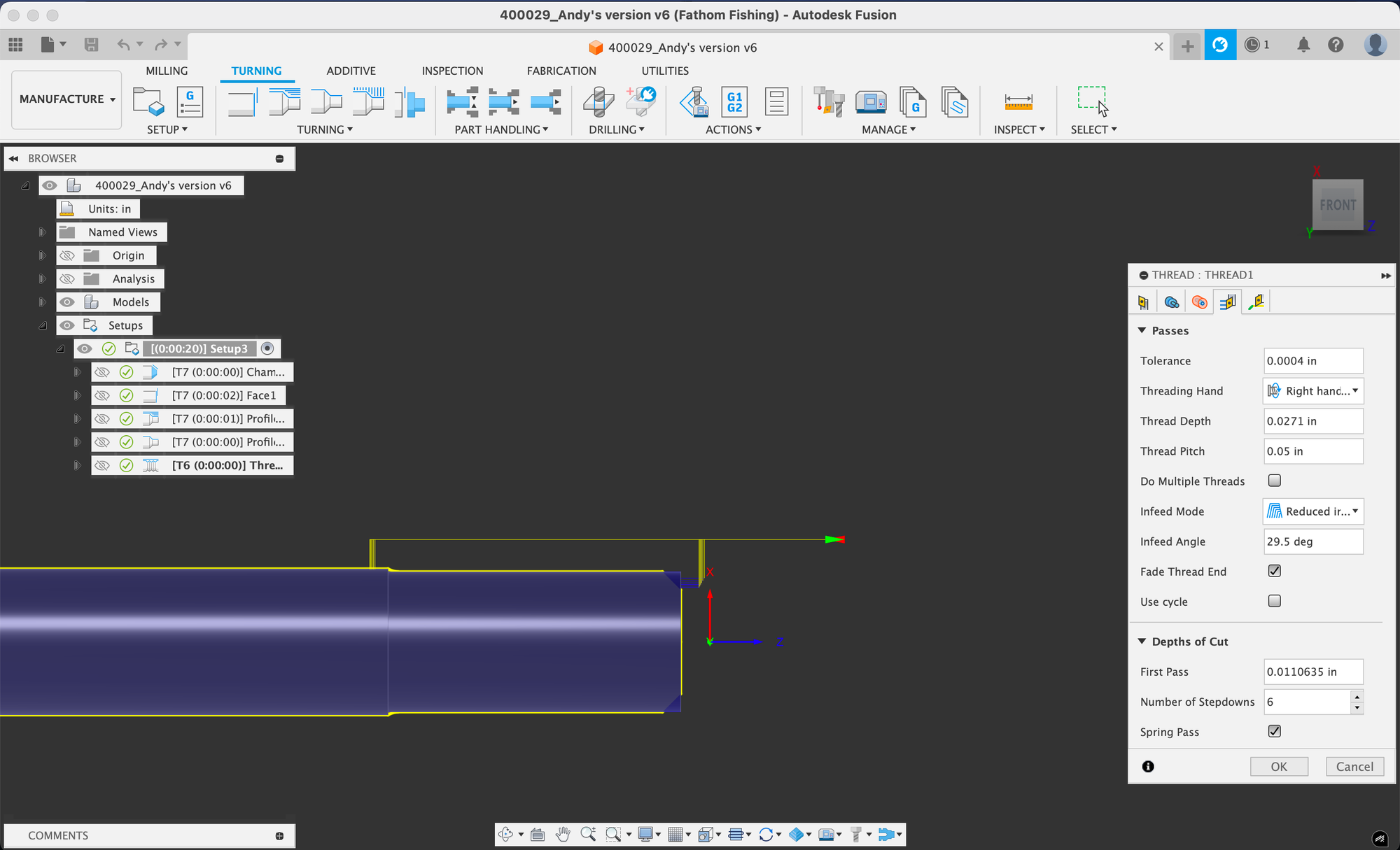

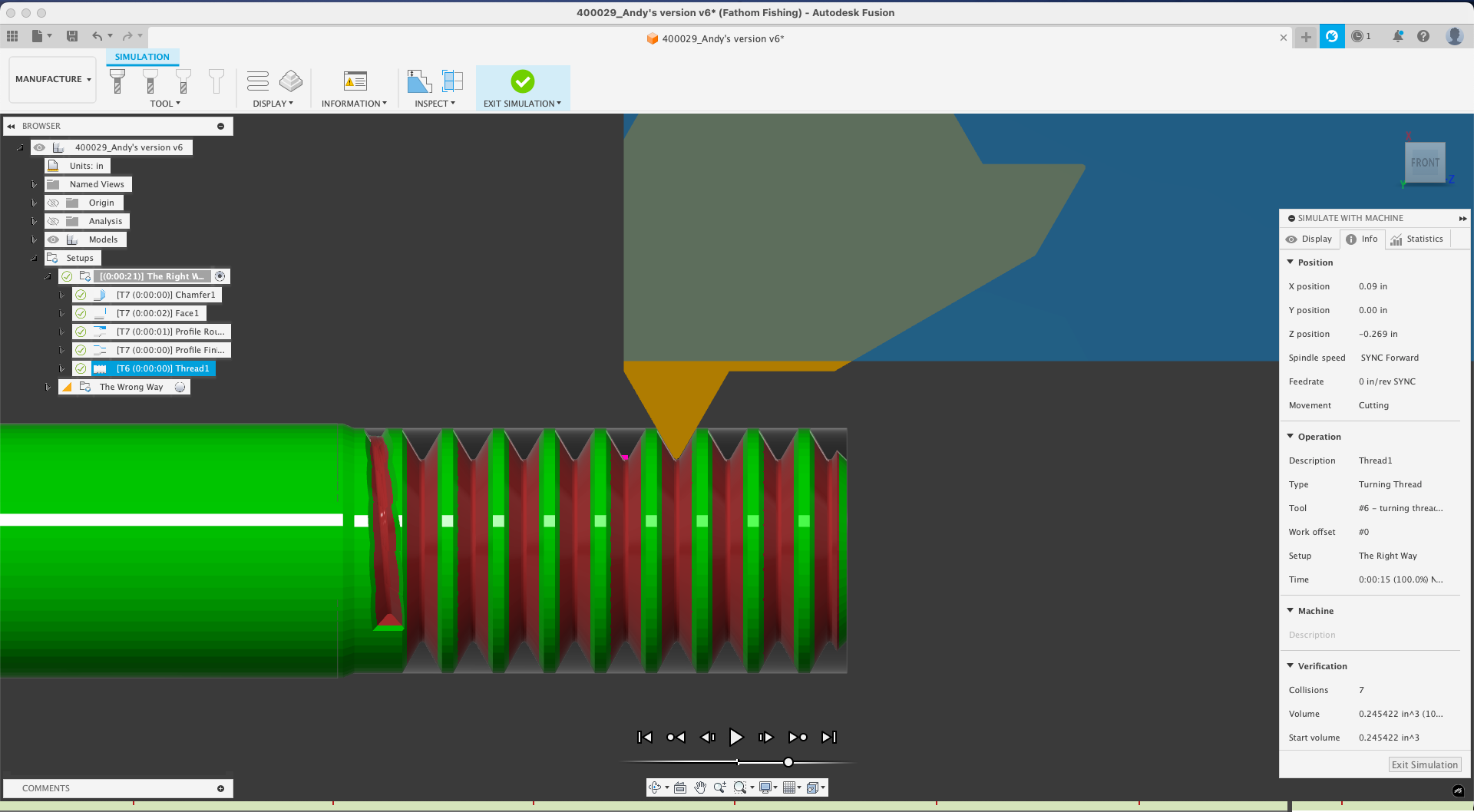

When you generate a program, or toolpath, for the CNC lathe to follow, you can't just enter these few seemingly simple parameters, or select from the most common thread types. The software actually needs about a million and a half different variables about the threads of your choice in order to compute. Cool, so let's figure those all out...

Attempt 1

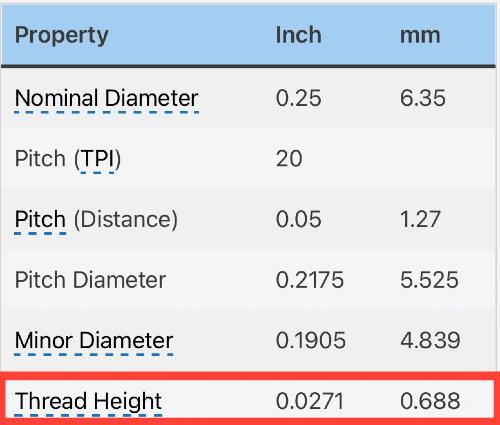

Amongst the last 4 digits of my social security number, my mother's maiden name, and high school mascot, is a parameter called Thread Depth. Fusion 360 is kind enough to explain this to us: Major Diameter minus Minor Diameter divided by 2. Easy enough. I pull up a table of thread information and find they've given it to us :)

At first, I assume Thread Height and Thread Depth are the same thing and use .0271" which didn't quite work the way I expected. The toolpath only turns down the minor diameter to .1960", not the .1905" that I expected...

Then I start looking at a few other tables of data, running calculations, and learning a few things...

(Major - Minor)/2 = Thread Depth

(.2500 - .1905)/2 = .02975

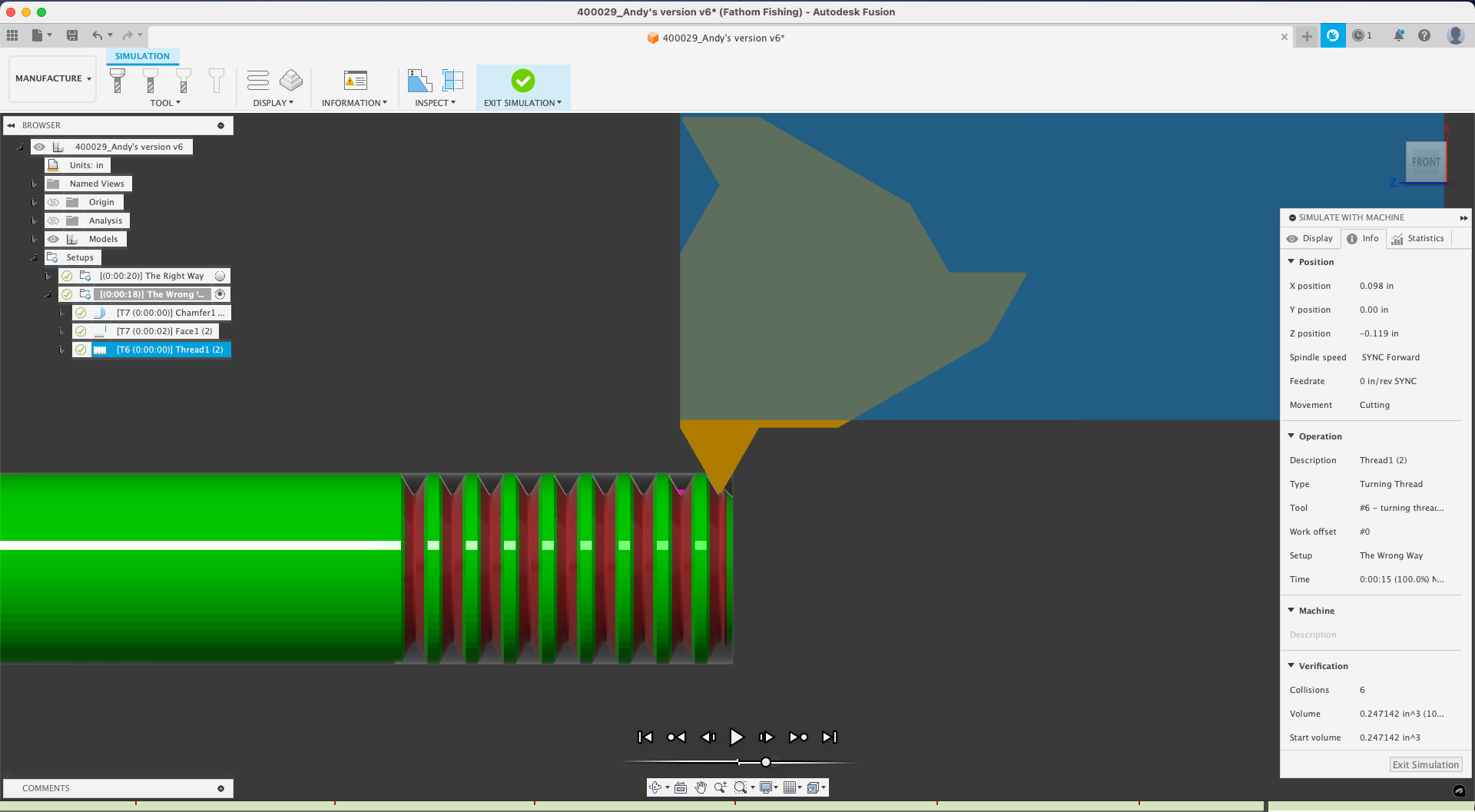

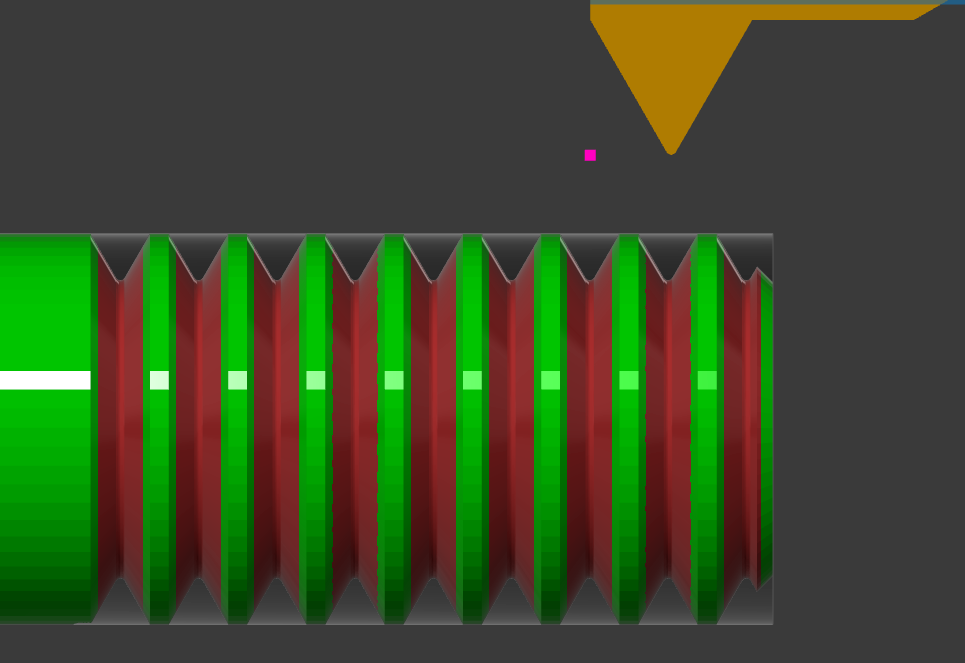

Okay, this time I run it with a Thread Depth of .02975" and the simulation properly shows a minor diameter for .1905"... But I still can't thread a nut onto my part!

Get Screwed

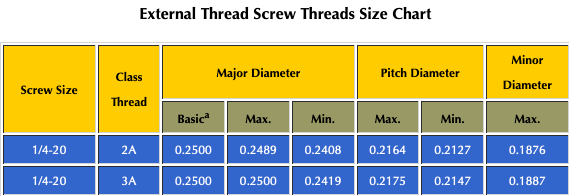

As it turns out, even my updated math doesn't work. .25" is the basic major diameter, but not the major diameter. The major diameter of a 1/4-20 class 2A external thread is actually anywhere between .2408" and .2489". Also come to find out that the maximum Minor Diameter isn't .1905" either, it's .1876"?

At this point I feel like I'm at the center of some kind of conspiracy or mass threading propaganda. What does Big Thread not want me to know?

Run the numbers again...

(.2408 - .1876)/2 = .02660

(.2489 - .1876)/2 = .03065

Wait, doesn't that mean .0271" should've worked when I initially cut the threads??? When I cut the threads initially, they seemed far too shallow, so I'm inclined to believe that a deeper thread depth makes sense.

A Revelation

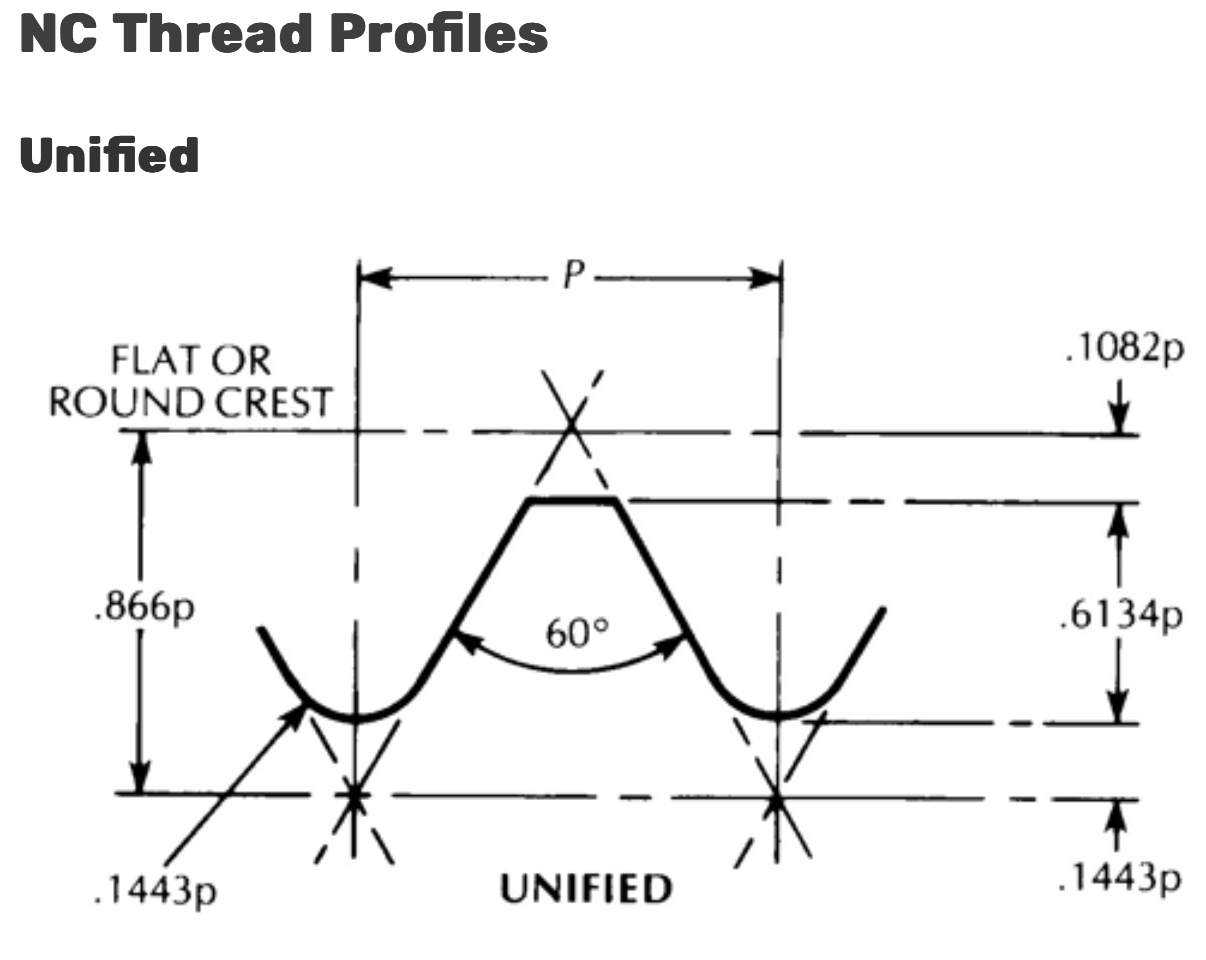

Then I came across this figure, which made things far more intuitive and helped me connect everything back to the software generating all my tool paths...

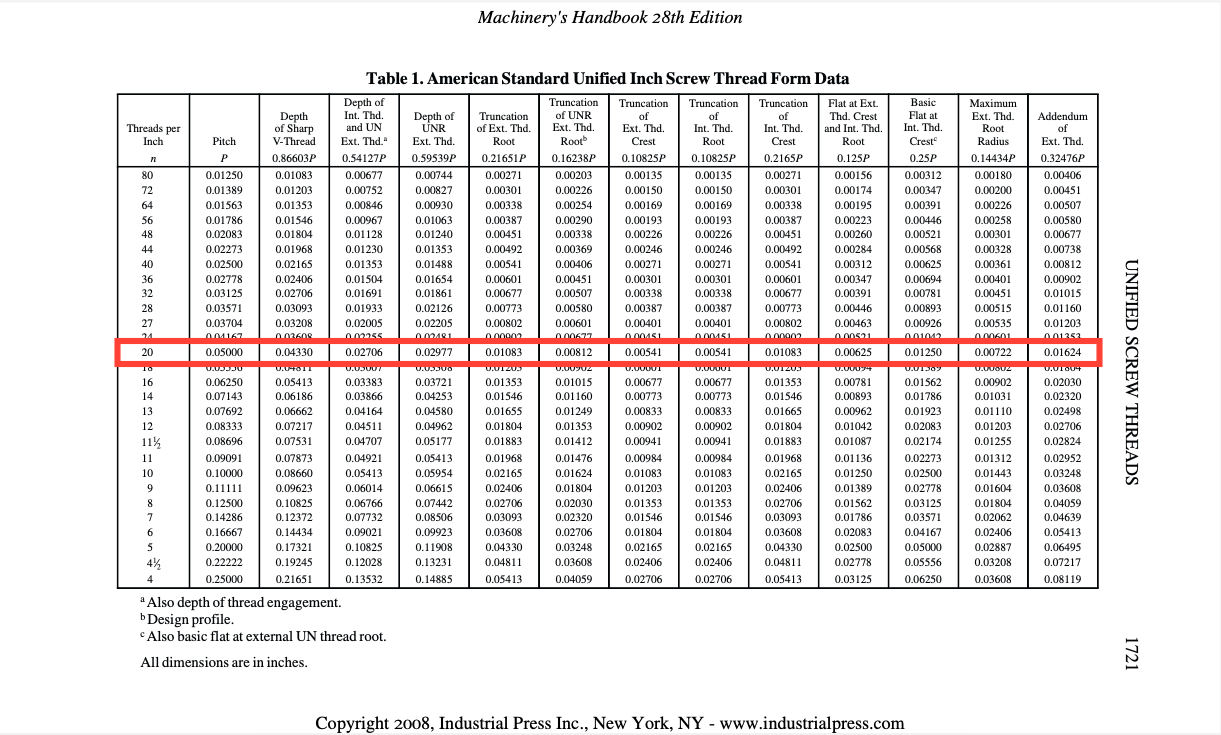

All of the depths are a function of the thread pitch, and it matches up with this table from Machinery's Handbook.

I also realize that the computer uses my geometry selection to set the major diameter, from which it subtracts the Thread Depth I provide it. Despite machining the proper .2408" diameter, I've been selecting the basic diameter, .25" for generating the toolpath.

Profit?

.6134 * Thread Pitch = Thread Depth

.6134 * .05 = .03067

Cool, we're getting places! Let me model the actual major diameter, and use the correct Thread Depth from above.

I think this will solve all my problems.

At least I'm pretty sure, but for all I know, I could be completely making this up and seeing what I want to see. Maybe all my issues are just a because my part is a wiggly wet noodle... I won't know until I head back to Boston and can try it out again, but I'm hopeful.

This concludes more than you ever care to know about threads...

Wins

Return of Dark Beer

I'm a sucker for a dark beer. As everything cools off a little bit, the wizards of craft breweries across New England grace us with their newest porters and stouts, and I for one am here for it.

Losses

Daniel Ricciardo

What a legend! I hope he finds another seat, or maybe even better starts up a Baja or WRC team. Ripping a rally car across the desert, or snowy forests of Scandinavia seems really fitting for him. Until then, he'll be greatly missed.

I think that's enough for now

Hopefully there was something entertaining or insightful there for everyone!

I've been doing a little bit better managing everything going on and taking things one step at a time. There's still a pretty big hole to climb out of, but I'm feeling good about it.

Trying not to get my hopes up too much, but there's a lot to be excited about this month:

- Applied to pitch Seaport Systems at a few pitch contests this month

- Finishing an application for an accelerator program this week

- I'll hear back about it at the very beginning of November

- Several grants I applied to a while back should release decisions shortly

Speaking of, get excited for.....

The Train Track of the Day!

Street Fight - Smallpools (Apple Music | Spotify)