Building Hardware

There is no better feeling than building something with your own hands. Literally anything. It's fascinating to think about! I get the same rush from machining a new part, 3D printing a prototype, and cooking a good meal! The physical manifestation of your hard work and effort is just unparalleled. I discovered it playing with LEGO when I was six, and I've been chasing the high ever since.

Creating a physical something is fundamentally very different than an intangible good. In writing, you're trying to convey an idea or a thought as it is in your head. There is no way to perfectly represent that idea and all the context only you can have. That idea as it is in your head is perfect, and you could spend a lifetime detailing, explaining and communicating it, but there will always be something subconscious you can't translate or explain. No matter how hard you try, nobody else will ever think about, or understand something the way you do. But a physical representation will always be the same. For you, for the first person you show, to the last person you show.

I think the joke goes: What do you call someone really smart, but can't for the life of them communicate that? An engineer. I guess it's no surprise then, that I prefer to express myself and my thoughts as tangible objects, which makes the fact that I'm trying to communicate this as a blog even more ironic.

I started Seaport Systems to help fishermen, aquaculturists and researchers (among others) understand the ocean so they could operate more effectively. With oceanographic data fishermen could track how much lobster they're catching and correlate that with certain environmental variables (temperature, dissolved oxygen). Aquaculturists could monitor water quality and predict harmful algal blooms, or predict growth over the course of their season to ensure they're meeting demand.

My original pitch, not too different than it is now, was that I would develop low cost sensors, sell the sensors to fishermen and aquaculturists, then help them tap into the data they need. From the first time I gave my pitch, I was told "hardware is hard" and to focus on the data - go get the data somewhere else and serve it to your customers.

I think that's pretty easy advice to give, and they're not wrong. Hardware is hard. It's also risky. But it's incredibly rewarding and absolutely necessary.

Investors hold the keys to the money, so of course they want to minimize challenges and risks to their investments, hence the advice: steer clear of hardware. I've talked to plenty of investors, specifically in the blue tech space, and they love the idea of enabling ocean industries with data, but historically haven't been interested in funding hardware needed to collect the data itself. "Leverage existing data, use offshore observing networks, use satellite data"

This would be great advice if those sources actually provided the data necessary, but either the right data points aren't being collected, or the data isn't being collected in the right spot at the right frequency. I've worked for oceanographic institutions, I've lived the world of oceanographic data for years, and I can tell you the data just does not exist (yet). In all fairness, I think blue tech investors have become more aware of this, and I've seen more interest in the hardware space in the last year or so, but I hate that people are coming around to hardware out of necessity, when we used to cherish physical goods! (Related book recommendation).

I've sat here, struggling to figure out how to express my love of hardware. Why am I defending it? After some thought, I think there's an emotional/spiritual connection I have (and why I've been too stubborn to listen to some really smart business people who told me to set it aside). Having worked in or with various hardware companies, I think there's also a business case that's far too easily overlooked.

Naturally, I have a really hard time communicating my thoughts, and as I said earlier, something physical speaks for itself. The burden is taken off of me to describe something to someone when I can just hand them the physical manifestation of my thought. It's easier for me to contribute and convey information in the form of something physical. Hardware also inherently and immediately demonstrates a certain proficiency with a variety of tools required to manufacture it. Whereas a professor has a CV to back up a new paper or study, and relies on people knowing their credentials to know if that paper is worth reading; if someone holds a beautifully machined, or incredibly intricate 3D printed object, the skill needed to create that thing is obvious. Finally, there's the pride I take in fabrication. While it isn't necessarily unique to hardware, I think that makes it far easier to appreciate.

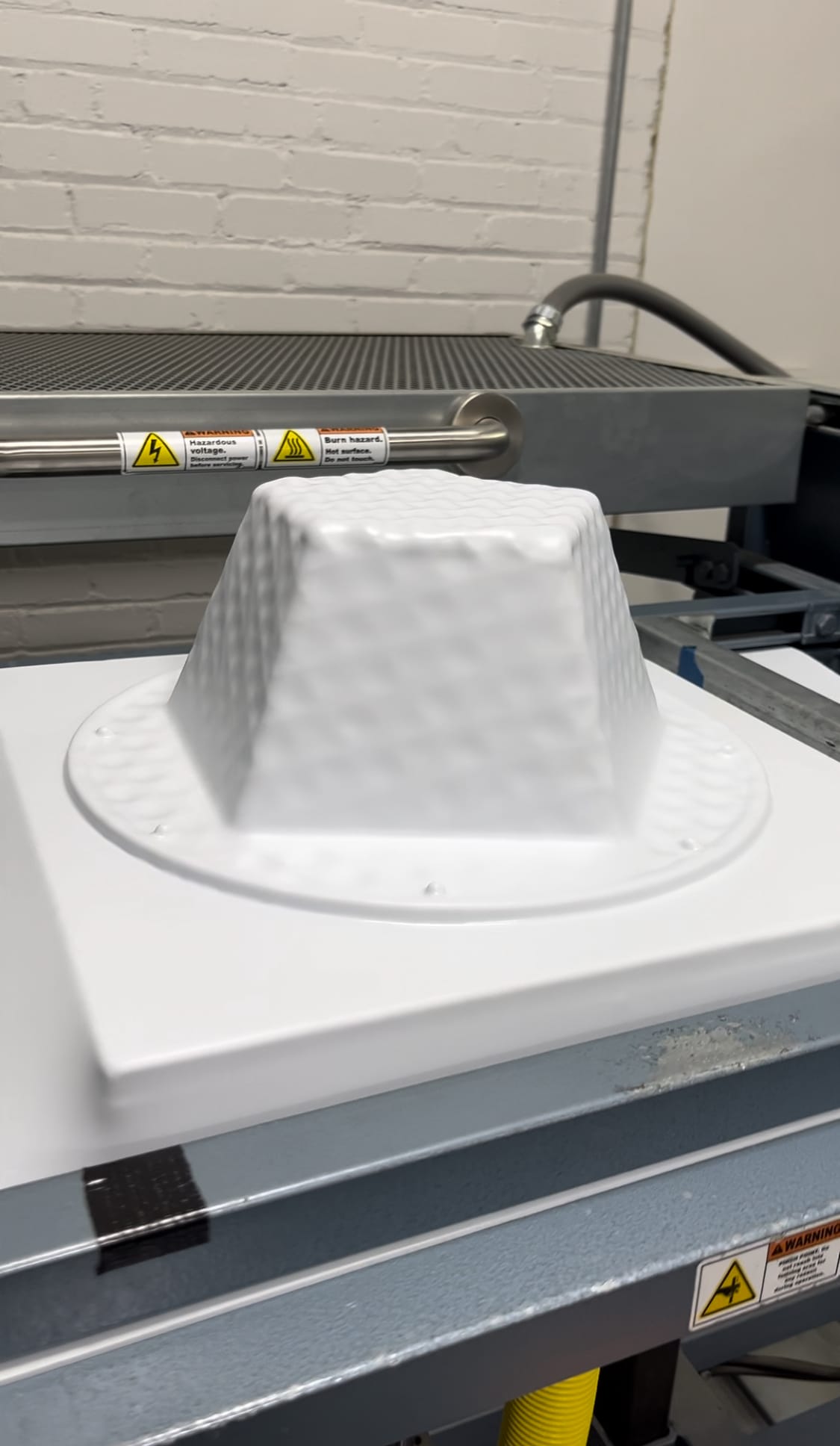

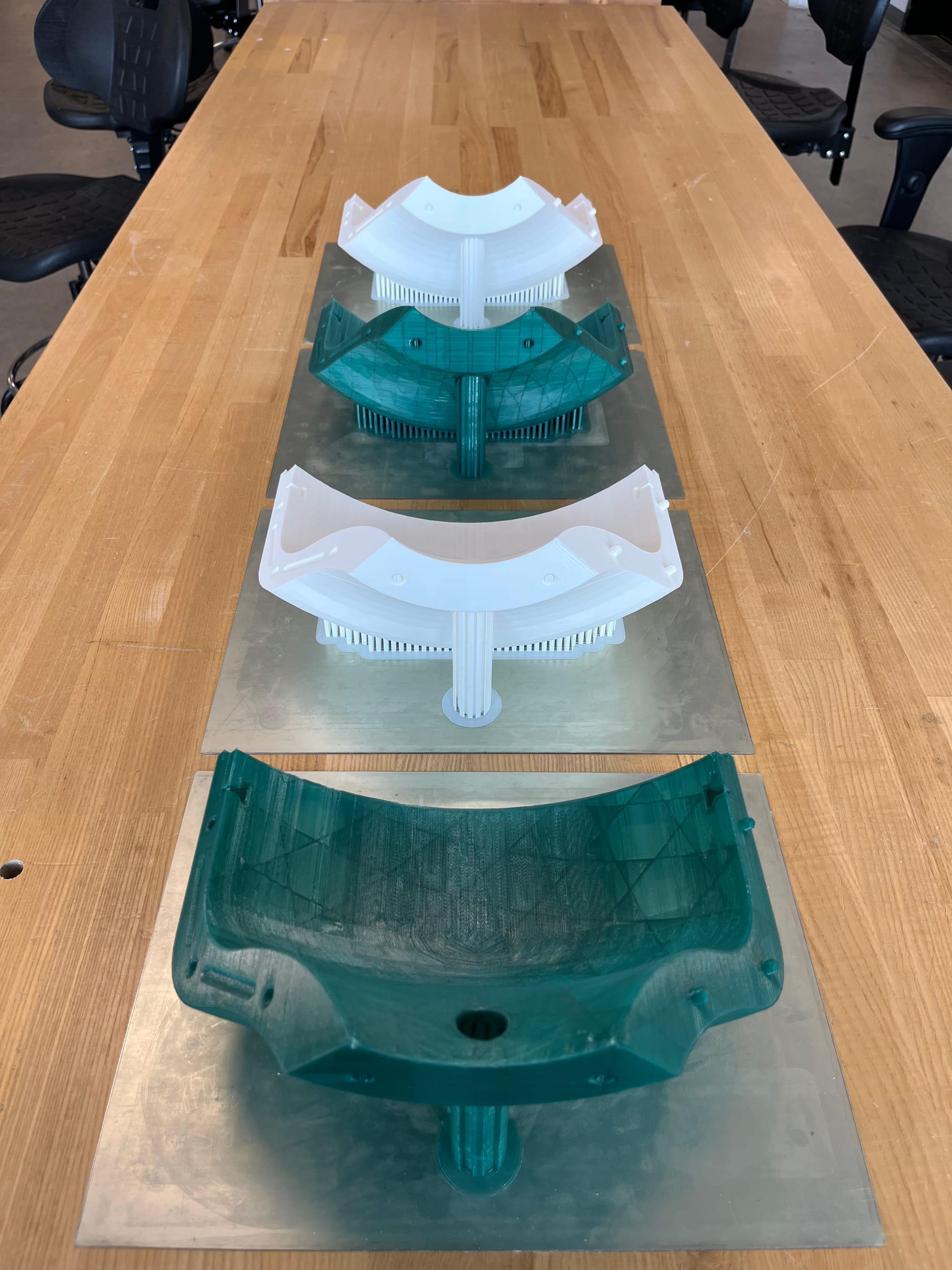

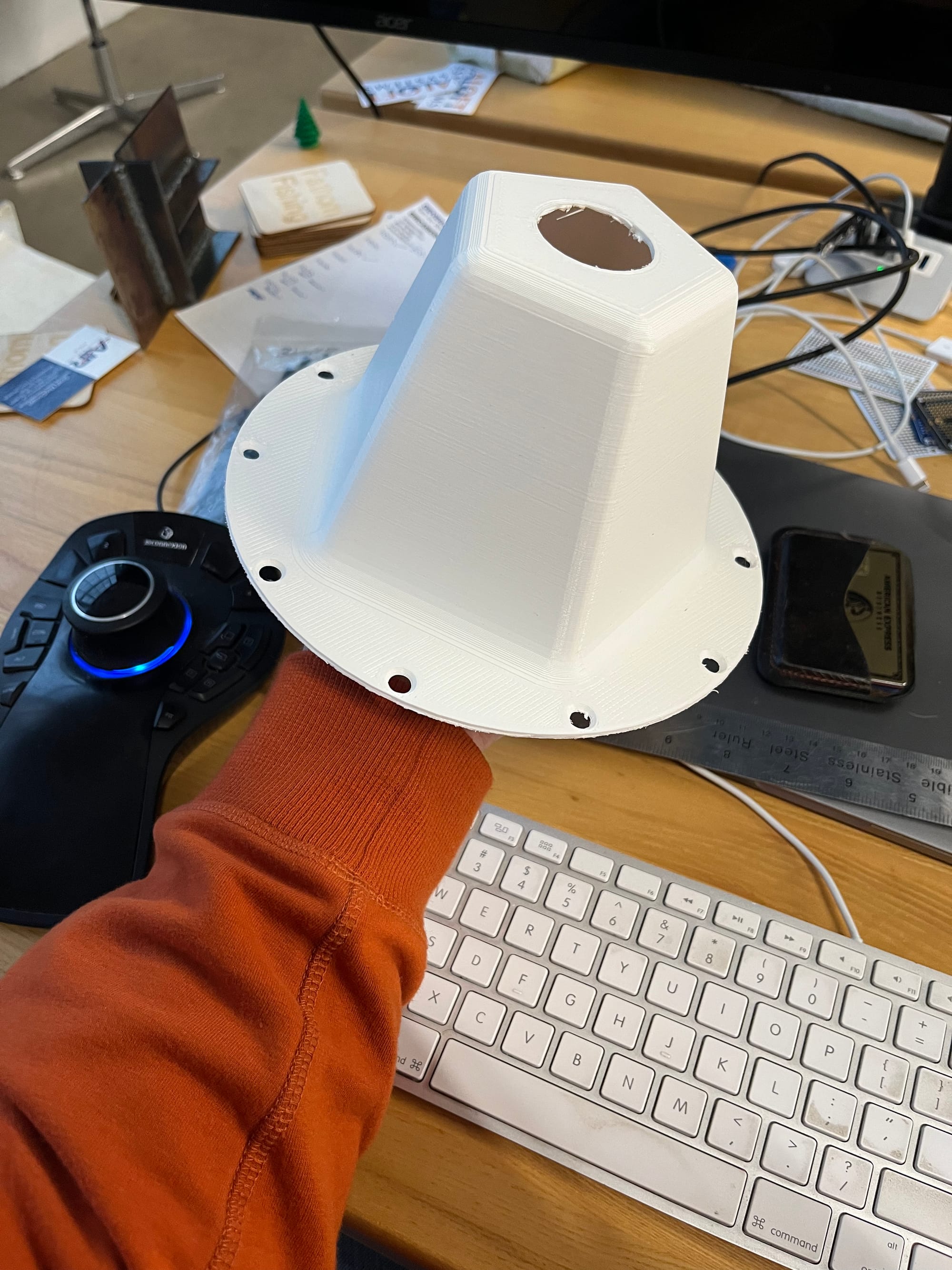

A variety of prototypes, all manufactured using different tools and techniques

Thoughts, ideas, philosophy are all important, but without tools, we would have never evolved. Things couldn't operate. Hardware and physical things give us the privilege to think about theory. Sometimes that privilege doesn't always exist. When I worked for Woods Hole Oceanographic Insituttion, I used to go out to sea on a research vessel where I would help incoming scientists every few weeks wire their instruments up to the Alvin submersible. The first couple of cruises had a research group that was testing their own novel probe designs. Normally they'd be studying biology of all sorts of deep sea creatures, but they couldn't. Not without new specialized probes to detect certain water quality characteristics. It takes a lot of passion and drive to step up to the plate and create something that doesn't exist. This group did, they invested a lot in hardware so they could study what they cared about. And for every person ready to do that, there must be at least 10 who would quit. Where would we be if we just gave up on everything that was kind of hard? That puts the real power in the hands of people ready to build!

Proof I actually worked on Alvin - and am good with birds

If as a business, you rely on the products of someone else, you're putting yourself at risk. That's essentially the whole field of supply chain management - managing suppliers, making sure you aren't exposing yourself to too much risk. Look at all the goods we have made overseas and the impact the COVID-19 pandemic had on supply of those goods. First basics like toilet paper and meat; but soon things like computer chips. Of course this rocked nearly every industry, but none as publicly as the car companies. I'm not saying that GM and Ford should be producing every chip they need for their cars, but the example illustrates the risk - you're beholden to everyone else you rely on. A slightly more niche example that ties the story closer to data: Apollo. Apollo was a 3rd party app for browsing Reddit. It used freely available APIs to Reddit data. It was widely beloved and quite successful, but only until Reddit decided no more. They essentially shut down the data pipeline overnight and Apollo was done. In the SaaS space, they've coined their own fancy term for it: platform risk; but it certainly isn't unique to software, as Detroit found out. It's the same risk we take trusting GPS for so much critical infrastructure, when the government (ours or others) could choose to cease its operation at any moment.

When you make things yourself, you control that risk. Yes it's hard, yes it's risky, but I would rather that every day of the week over trusting someone else. Growing up, every kid is told "own your mistakes" "don't make excuses" and it never really sunk in when I was little, but it sure has now. The auto manufacturers, Apollo, and GPS are all extreme existential examples, but the benefits present themselves far before that point.

Over a summer at SpaceX I sat in a set of desks surrounded by build reliability engineers (BREs). They were responsible for asset tracking, traceability and ensuring that only quality parts flew made it to flight. It isn't the sexiest jobs, but it's incredibly important. A huge part of SpaceX and Tesla's philosophy is vertical integration, bringing in as much of the process in-house as possible. After sitting around the BREs for a summer, I could see why. I don't have any concrete evidence, but I feel confident saying that a majority of the quality issues in production come from suppliers, and correcting the issues at the suppliers was exponentially harder. A supplier will almost always pass off the bare minimum, and they can't internalize your urgency. There's never enough time to do it right, but always enough time to do it over.

The same quality and traceability challenges have presented themselves at every single job I've been at. Some handled the risk and subsequent issues elegantly, others with what I can only describe as brute force. Counter example to SpaceX's vertical integration would be Boeing, who have consistently outsourced as much as humanly possible, and I don't think I have to tell you how that's going, but I will anyway ;). Since I hate meetings, confrontation and mindless talking, and that's all the BREs and project managers ever did, I swore that when I did my own thing, I'd do as much myself as humanly possible.

And I don't mind one bit. Besides everything I've already said, I just like building things. I think it's therapeutic. Running machines, turning knobs, engineering supply chains, and developing processes. I love it all. I'm incredibly passionate about building, and one day I I hope to revisit it. Hopefully after getting more practice writing!