🫠 - it is what it is - 🤷

The last couple weeks have seen some high-highs and low-lows. Finalization and delivery of the first DB-X batch over the last two weeks is obviously a huge milestone worth noting. I also got word from Ferda Farms that after several weeks, Mother Nature had claimed their XB-X buoy, which is obviously not news anyone wants to hear.

It's remarkably hard to reconcile and move forward from simultaneous good and bad news. When you get bad news you can tuck your tail between your legs, collect yourself, then deal with it. When you get good news you've obviously got the green light to celebrate, party, and treat yourself. But when these are at odds with each other, what the hell do you do?

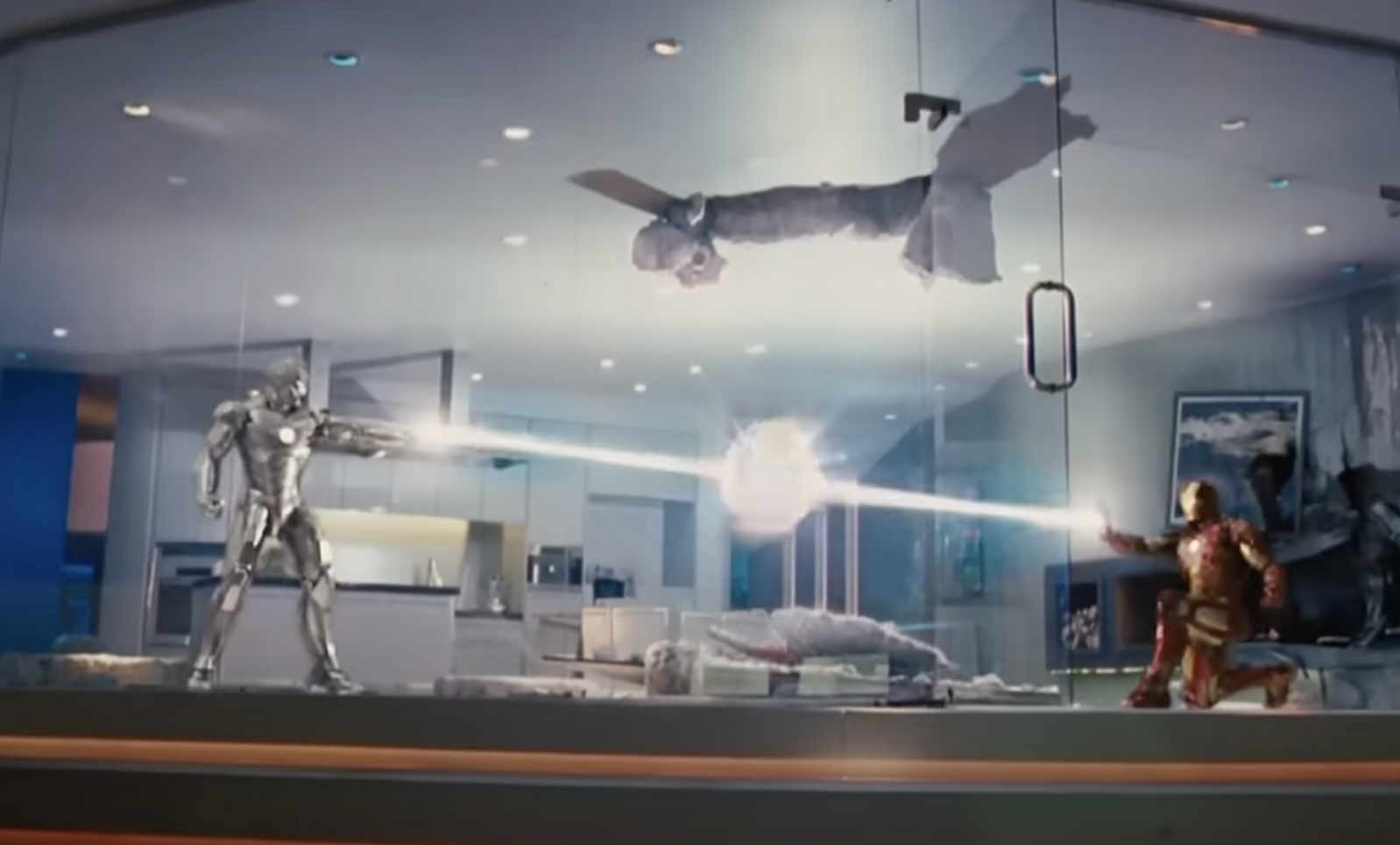

It feels like in the movies when the hero and villain go to battle each other, then at the climax they both simultaneously cast spells or fire their futuristic ion laser beam thing, and they both counteract until everything explodes and the battle is over without resolution, leaving the landscape in absolute carnage.

I'm certainly not being dramatic whatsoever in making this comparison...

So here I am, trying to pick myself up out of the wreckage and figure out what to do next.

There's demand and orders for more buoys, there's more work to do to fulfill grants I've committed to (and fallen behind on), but these are such big goals I haven't been able to break them out into reasonably accomplishable milestones.

A big reason that task management has become more difficult is that the value of my time has changed drastically. I'm finding that a lot of the work occupying my time is very simple tasks I could easily teach someone else, or otherwise offload. That being said, I'm in a very weird valley where I don't have enough time to handle all that relies on me, but the orders I have just aren't enough, and certainly not regular enough, to be able to procure someone else's time.

There're plenty of programs through a variety of State and non-profit groups in Maine and Massachusetts that can fund interns and provide funding to help bridge these types of situations for small businesses. I met with a friend and fellow founder this week who is an all-star with these kinds of things. He's built his business pretty successfully making incredible use of a lot of these types of programs. It's allowed him to focus on what he's uniquely good at and multiply his efforts. He's been trying to convince me for months to take advantage of the funding out there available to hire interns, and I think he's finally gotten the message through my thick thick skull.

Last Week (two, really)

DB-X Delivery

I delivered the mostly complete DB-X buoys to Coastal Measures two weeks ago - this was the main body, ballast weights, top caps, electronics stacks and batteries. Despite the hour and a half drive taking over three and a half hours, the handoff was largely uneventful but mostly a sign of good faith. Without fasteners, fins and their associated hardware, the job wasn't done yet - close, but close doesn't count.

There were three major parts needed to finish out fabrication and fulfillment. Each DB-X gets 3 fins, 6 fin mounts, and 6 fin stabilizers, so over 10ish buoys, a ton of pieces...The fins are 6"x12"x.125" sheets of high impact polystyrene (HIPS) - these are simply laser or saw cut. The fin mounts are 3D printed from polyethylene terephthalate glycol (PETG). And finally the fin stabilizers are CNC machined from 6061 aluminum. Designs were done - the hold up was largely just long cycles on the 3D printers.

DB-X Software

Wednesday of this past week I drove back up to New Hampshire to have a final working session with Coastal Measures before they handed the buoys off to their first customer!

The DB-X software was most of the way there, but our efforts were heavily focused on bulletproofing things. On your computer at home or work, you're there operating it, if things stop working you might hit CTRL+ALT+DELETE, stop a program and restart it. This can be annoying but ultimately fine - it happens rarely, the impact is generally speaking low. But for a device that isn't supervised by a conscious human being who can immediately intervene, the software that runs the DB-X has to be autonomous enough to deal with any errors that arise, and be able to handle them gracefully.

This took a lot of time, and experimenting, but we got it done. A perfect demonstration of the Pareto Principle:

80% of the work takes 20% of the time, 20% of the work takes 80% of the time.

It was actually really cool being under the gun working with Josh that day. I learned a lot from him. It reminded me of how incredible working on a good team can be.

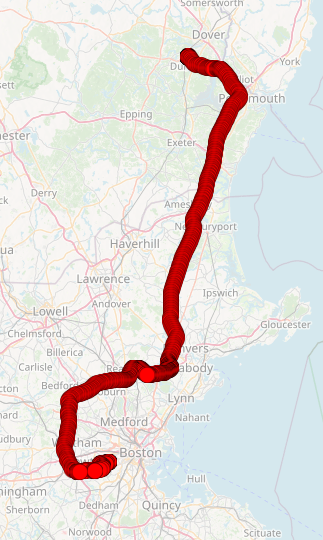

After a full day of trying to bulletproof the buoy software, I packed up, threw my development DB-X in my truck and drove the couple hours home. It was really the ultimate test of the datalogging and telemetry systems: significant distance/duration; power cycled a few times when I stopped to run a couple of errands; in and out of cellular dead zones. And it all went perfectly! Got a great looking track, no dead zones or drop outs!

Next Week

XB-X Rebuild

Really rough catching the news that the deployed XB-X sank. They hauled it back up, and I've got a few ideas about what happened. I think it's a case of compounding effects. One little insubstantial thing led to another slightly more substantial thing, which slowly led to more and more major problems.

Originally, I was hoping to swap out one or two subsystems at a time until the XB-X was fully fleshed out, but it looks like I'll run pretty much a full rebuild this week. I'll redesign the probe insert fittings, use potted penetrators to pass probe wires into the electronics enclosure, and redesign the hull/enclosure mating system to eliminate the latches and improve the watertight seal.

Wins

DB-X Delivery

^^^ see exposition above.

Reading Books

The Toyota Way has been taking me a long time to read but I'm not being lazy about it. I'm just spending a lot time trying to comprehend and reflect on what I'm reading, chapter by chapter.

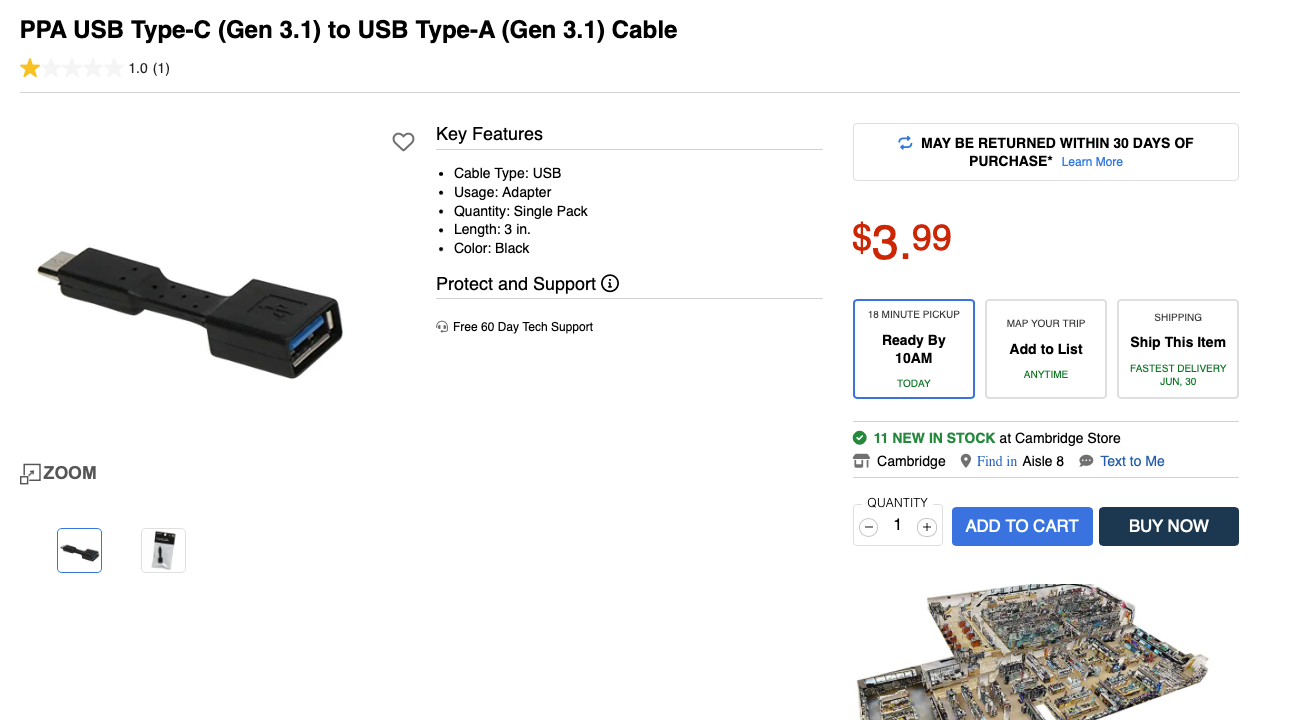

In the spirit of The Toyota Way, I have implemented one of the simplest, most incredible quality of life improvements: a USB-C to USB-A adapter for my MacBook.

When I'm machining on the CNC mills at work, I have to export tool paths to a flash drive, then plug that into the machine. For the last couple of years, I'd either walk back to my desk across the shop, or I'd unplug my laptop dock from my monitors, keyboard, etc. bring it into the machine shop while I worked, then spend 5 minutes plugging everything back in when I was done. For $3.99 at MicroCenter, I've already saved myself well over an hour of hassle in the last two weeks!

Walking

For the longest time my daily commute has been Green Line -> Park Street; Red Line -> South Station; Building shuttle/Silver Line -> Work. During one of the Red Line shutdowns in March, I started walking the leg from Park Street to South Station. I had never considered it before, but it's actually phenomenal!

It's consistently a 10-15 minute walk, which is much better than the Red Line. The Red Line might be faster if there's no transfer time - but with the Red Line's dismal and volatile 6-20 minute headways, that half-mile stretch could very realistically take 30 minutes!

For now I get to stretch my legs first thing in the morning, take in a nice dose of vitamin D, and catch some fresh air before work. The walk is equally therapeutic on the way home from work. It's a peaceful transition from the chaos of work to relaxation at home.

Losses

XB-X Sinking

^^^ see exposition above.

Jury Duty

I've been summoned for jury duty later this year. It feels like a loss for now, but could be fascinating if it was an interesting case. Unfortunately, sitting still in a quiet windowless room for 6-10 hours is not really something I'm equipped for. I also have recently acquired a fear of being gaslit for reality TV for weeks on end...

In Other News

Merch, Baby!

The Seaport Systems Store is now open for business! We've got everything from environmental monitoring buoys to tee shirts to contemporary art. Free shipping across the board. Check it out! Merch orders placed before this Wednesday June 26th, ship with the first batch on July 1st, 2024!

110087/001 - SHIRT, TEE, LEFT CHEST

"The people need to know it's primo attire to get tacos in"

Thermoform Failure #1/2

Would look good in a frame!

Garbage like this ends up being praised all the time, after it gets framed and propped up on the walls of art museums and the homes of the wealthy elite.

Closing Monologue

For those of you Type-A people, I promise that by the time next week's edition rolls around, everything will be a little bit more organized, and the path forward for the next couple of months will be far clearer.

Thanks for reading as always!