I fell asleep last night at 10:31pm, writing this

Title says it all...

It's been an incredibly busy week, which is both good and bad. Lots of work done and great progress, but that leaves little time to write. Yesterday around 5:15pm I finally sat down to write the blog. I wrote for about half-an-hour before heading out to the train station where I sat at the bar waiting for my train and cranked out another few paragraphs. Kept writing like a madman on the train home. Ate dinner. Kept writing while Ashley watched a movie I didn't understand whatsoever despite it being a superhero movie starring Bruce Willis. I fell asleep on the couch, face in laptop with a half-written blog that just had "F" and "V" written out 13,000 times. My neck hurts now, but all in all I think this is a pretty good sign that shit.got.done this week.

Long story short, the blog is a day late. Bite me.

This Week

Hull

This is the most exciting update of the week, maybe even the month! In the first revision buoys deployed last year, the hull was the weakest link.

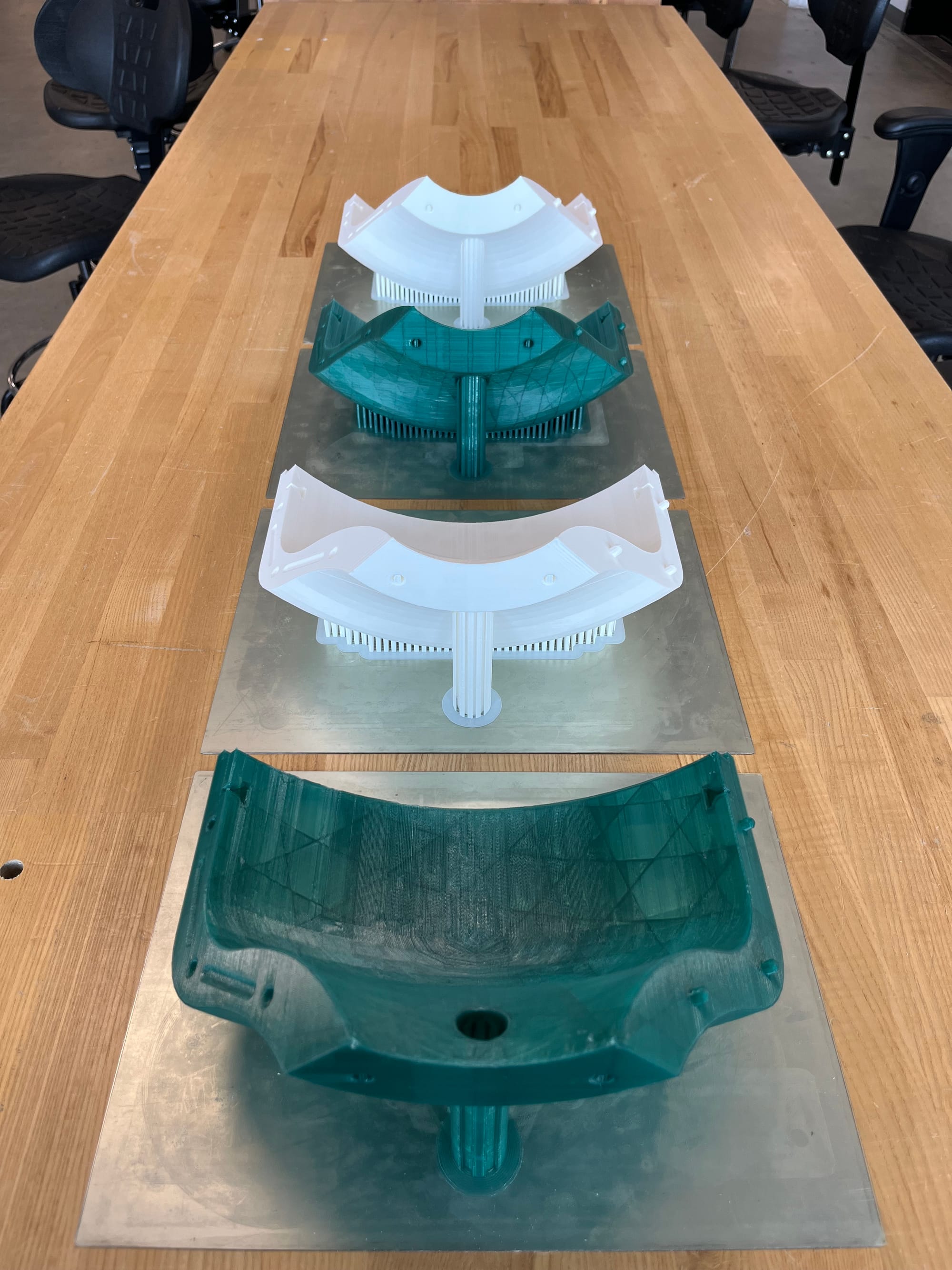

Revision 001 hull - made out of 5 3D printed parts, superglued together, before being coated in fiberglass and epoxy resin. That was a fine process for fit testing, and super early on the water testing but not much more. Unfortunately, I trusted it too much and it caused a lot of problems and delays when I tried to deploy longer term. Even with epoxy and fiberglass, the hulls weren't dimensionally stable, in fact, they melted in my truck on the way to test them one day. On top of that, I don't think they looked very good, and fabrication was a nightmare. When you're making a couple buoys, you can afford to spend a few hours on each hull, but when you want to make a couple dozen, that becomes really costly.

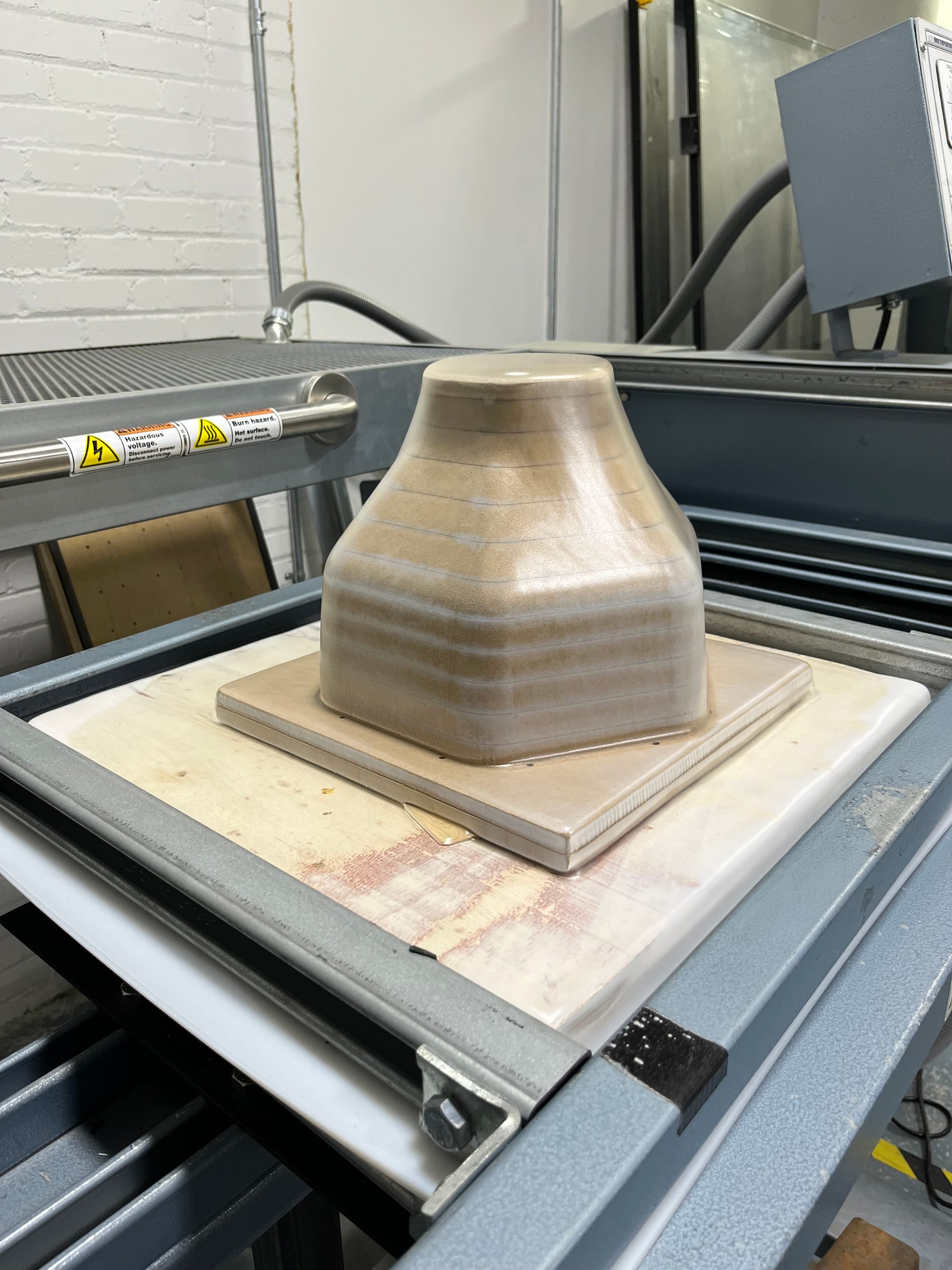

REV001 Hulls, they were okay

Revision 002 hull - vacuum formed. This is a much better process, especially when you know you want to build more than a few of something. Vacuum forming works by heating up a sheet of plastic 'til it gets droopy, pushing a mold the shape of the thing you want, up through the droopy plastic, then sucking all the air out from between them. The plastic takes the shape of the mold, and when it cools down you've got a lovely part! The trick is, vacuum formers aren't the most common piece of equipment around and you do have to invest in making a mold. Thankfully, you can make these molds out of cheaper materials like MDF (found at Home Depot for about $50 for a 4'x8'x.75" sheet).

There's plenty of choices for plastics, and this go around I tried high-density polyethylene (HDPE). In the past I've had good success vacuum forming polystyrene, ABS, PETG and a few others I can't remember.

PETG (same material pop bottles and that horrible plastic packaging you have to cut with the jaws of life before slicing your hand open) is great if you need clear parts, but is really brittle and sharp which makes post-processing your parts really tough. ABS is a good deal easier to work with, but HDPE really takes the cake. This go around I wanted to try HDPE. A lot of plastic automotive/off-road parts are made by vacuum forming HDPE. It's really strong, it's inexpensive, and also forms easily and cuts like butter afterwards, a no brainer.

I formed the first 002 test a couple weeks ago out of .125" PETG, a good learning experience, but it wasn't until this week I actually tested the .25" HDPE. It came out soo0 good. It fits perfectly into the top collar! I tried it with the radial o-ring seals and it looks like it's ready for the water. It isn't quite yet, but the progress feels incredible. What was my biggest downfall last season is probably one of the best parts on the new build so far. Funny how everything works when you've got a plan!

Hull REV002 Vacuum Forming

DB-X Antenna Testing

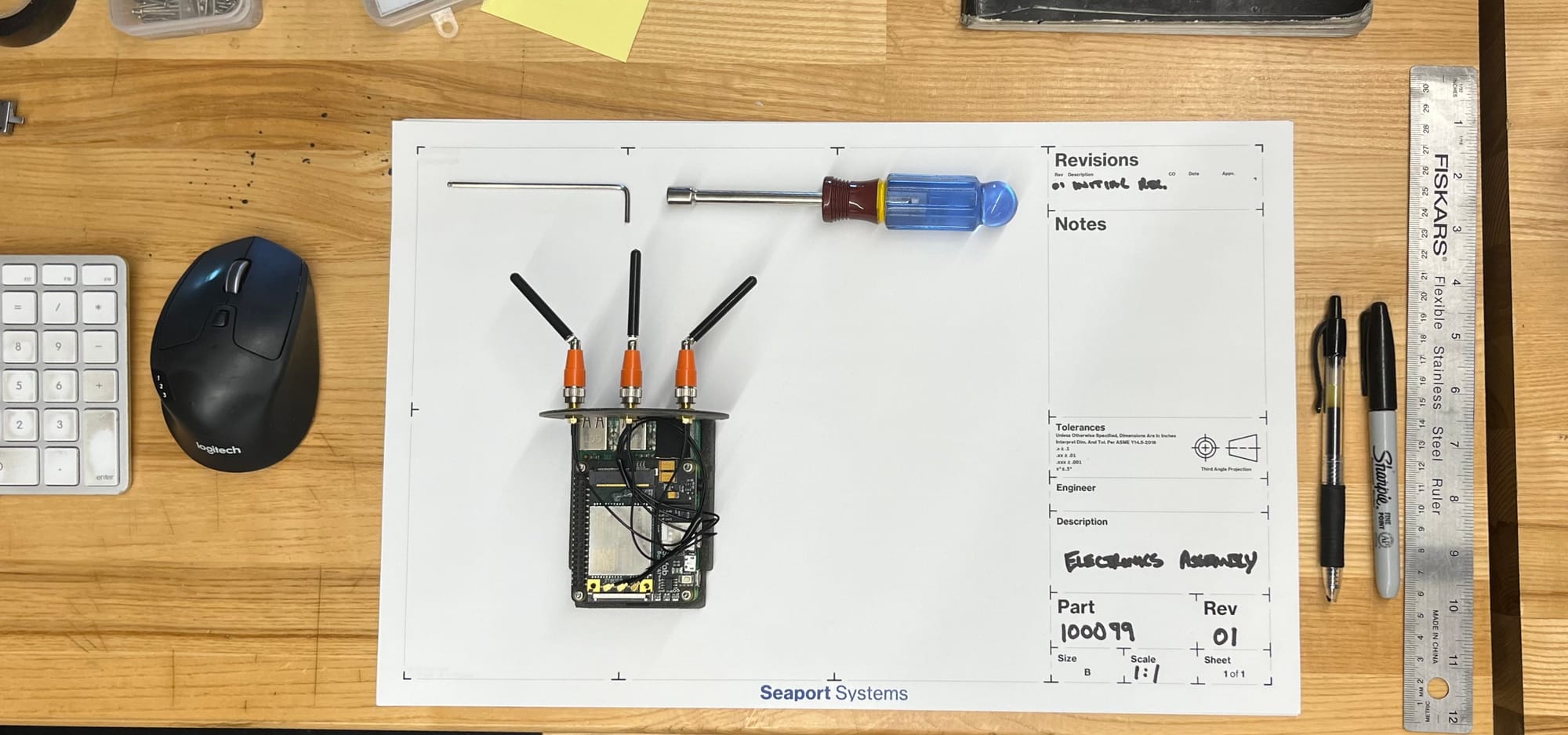

After getting punted the last couple weeks, I was finally able to get out of the shop to try out the DB-X communication systems. The DB-X uses a cellular modem to transmit location data from a GPS receiver. Both of those need good antennas, especially in close proximity to the water. I have two styles, a short stubby antenna and what I'll call a top hat. I think you saw them in an update a couple weeks ago. Both gave near identical results in the preliminary testing.

DB-X Antenna Testing

Cellular reception is commonly measured in RSSI, and I was getting -30dBi. I won't get into decibels, but feel free to give yourself a headache if you'd like. The shorty story is, cell reception was strong.

On the GPS side, I was looking at dilution of precision, or DOP values (although there's probably a better metric if I dive deeper into it). There's a handful of DOP values that can be calculated, but I think the most common are horizontal (HDOP, 2D position), vertical (VDOP, altitude), and position (PDOP, 3D position).The closer to 0 your DOP value the better, and anything about 20ish being unusable (I think, I read the Wikipedia page).

I was getting values between 6 and 11 which on gut feeling doesn't feel fantastic but I think is workable for now. DOP decreases as number of satellites in view increases, and while I was outside, I was surrounded by huge silos and trees, so that very well may have contributed. Consulting some friends who use GPS for pretty critical autonomous navigation applications, they require DOP values less than 1.5 for stable operation. So potentially more work to done, but I think the most important thing is to correlate DOP to something more meaningful. Does a DOP of 10 mean accurate within .5 feet, 5 feet, or 50 feet?

Website Updates

Nothing revolutionary or critical, but I did add the Applications page. My personal interest is in aquaculture, but there's no shortage of applications for low cost oceanographic data and I owe it to myself to highlight those applications to people who stop by the site.

Next Week

Top Collar (cont.)

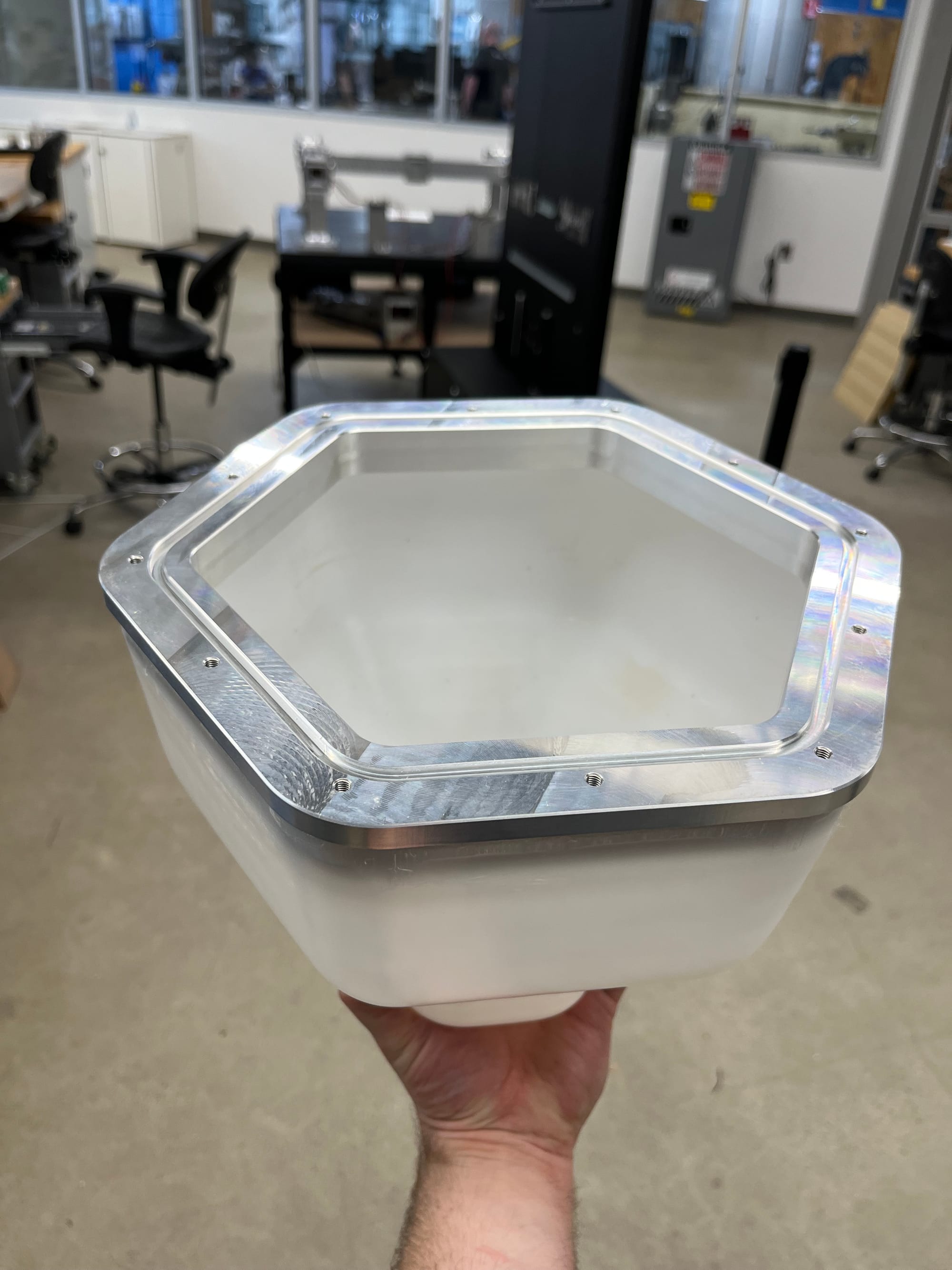

The first top collar came out fantastic and I'm super excited about it, but it's not without its flaws. Thankfully they're pretty minor, nitpicky issues and I have the luxury to fix them at this stage! The most notable fix is the two o-ring face seals. They're slightly different sizes, which I originally thought would be a good thing, but I've changed my mind. I want to wait to do some further testing before machining additional parts, but that should all be sorted out next week.

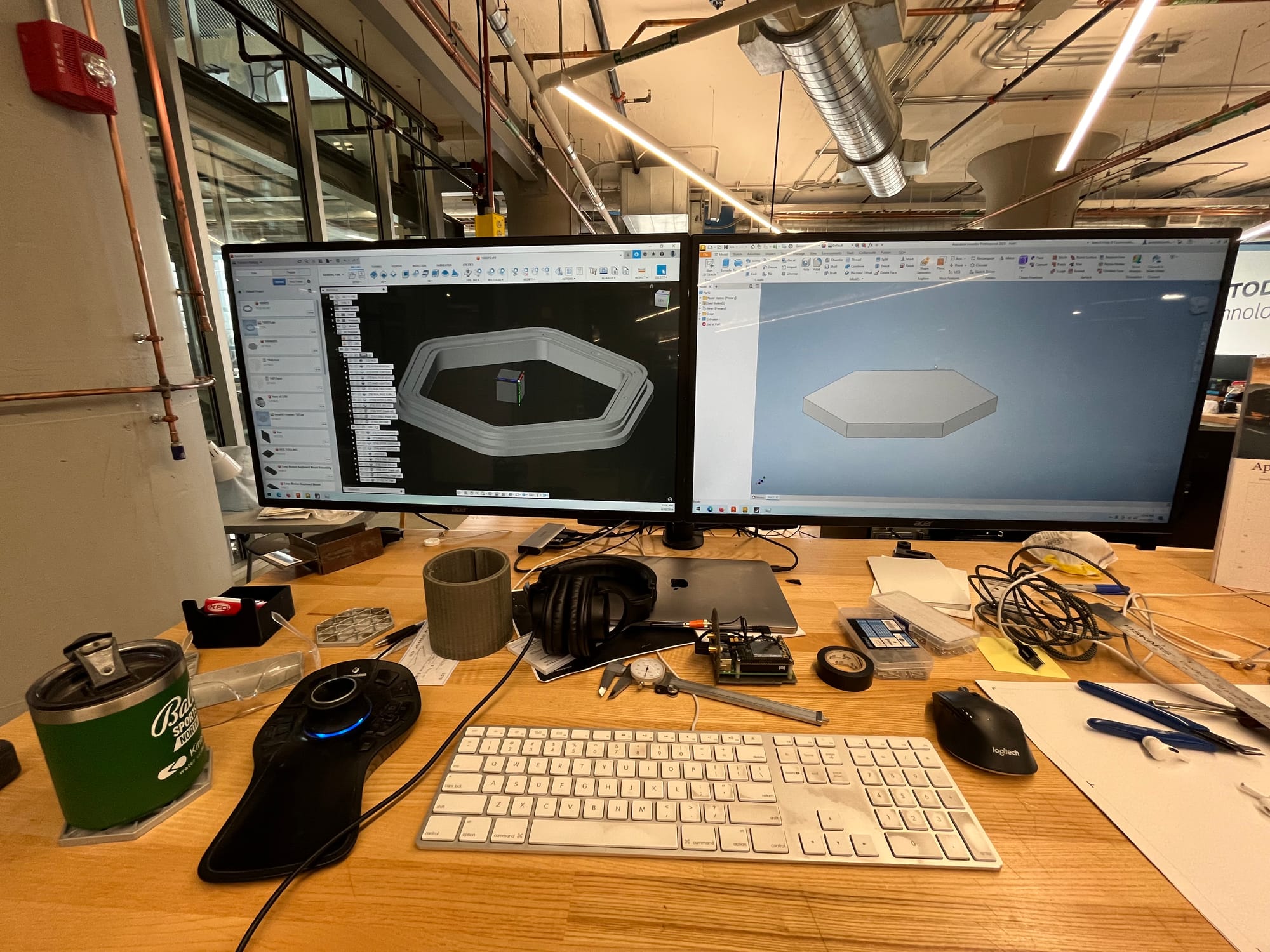

Top Collar seals lookin' sharp. Desk lookin' not so sharp

DB-X Internal Redesign

First couple of DB-X prototypes went well. After assembling, disassembling and re-assembling several times, I've identified a few shortcomings and have some fixes. Thankfully those are all 3D printed parts, so after some design work this weekend, I'll get those run off in some down time!

Wins

Hull

I've covered it enough already for this to be obvious I think.

Reading

On Tuesday, Ashley and I turned off the TV, put our phones in the other room and just read a book on the couch. It's insane that that feels noteworthy, but that's the world we live in these days...

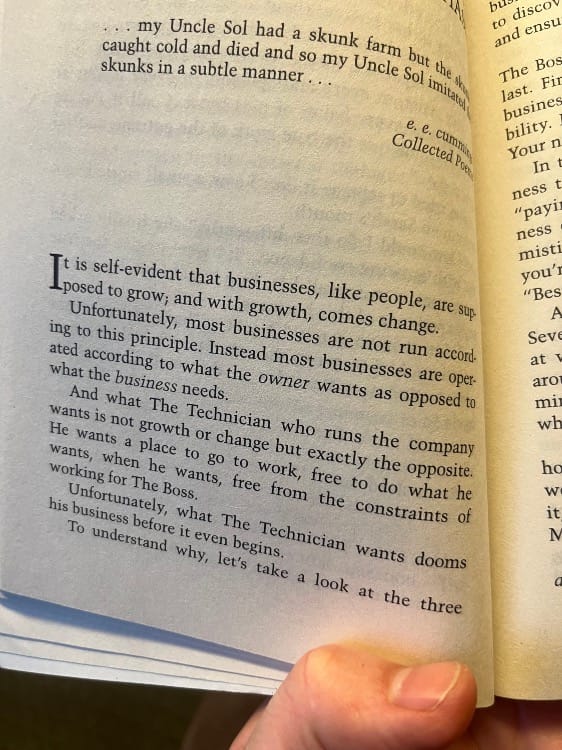

I started reading a new book, The E-Myth, recommended by John Saunders of NYC CNC and Saunders Machine Works fame. It looks at entrepreneurship through 3 personas within ourselves and how they're all at odds with each other: The Technician, The Manager, and The Entrepreneur. 100 pages in and the author has vocalized a lot of things I've never been able to explain about starting a company. I'll probably finish this one, but check back in next week for the full review.

Baseball Season Is Back!

I walked through Fenway last weekend and it was incredible, felt like home! Neither the Twins or Red Sox are doing particularly well, but I'll take it!

Losses

BU Men's Hockey

Good game, tough loss.

Microsoft

Trying to upgrade from Windows 10 Home to Windows 10 Pro might be the worst experience using a computer I've ever had. I haven't used Windows in the last several years and it's crazy how far its has fallen since I last daily drove it...

In Other News

Shout out to Jessie. In my quest to create the perfect merch for Seaport Systems, she sent me a corporate vest for inspiration!

Train Track of the Day

It's been a big Kanye week.